Food Plant Waste Pretreatment and CHP

Monogram Foods retained CTS Builders to design and construct an industrial pretreatment system to support existing production at the Martinsville, VA plant as well as a planned expansion.

Client: Monogram Foods

Location: Martinsville, VA

Services: Design Build, Construction Management

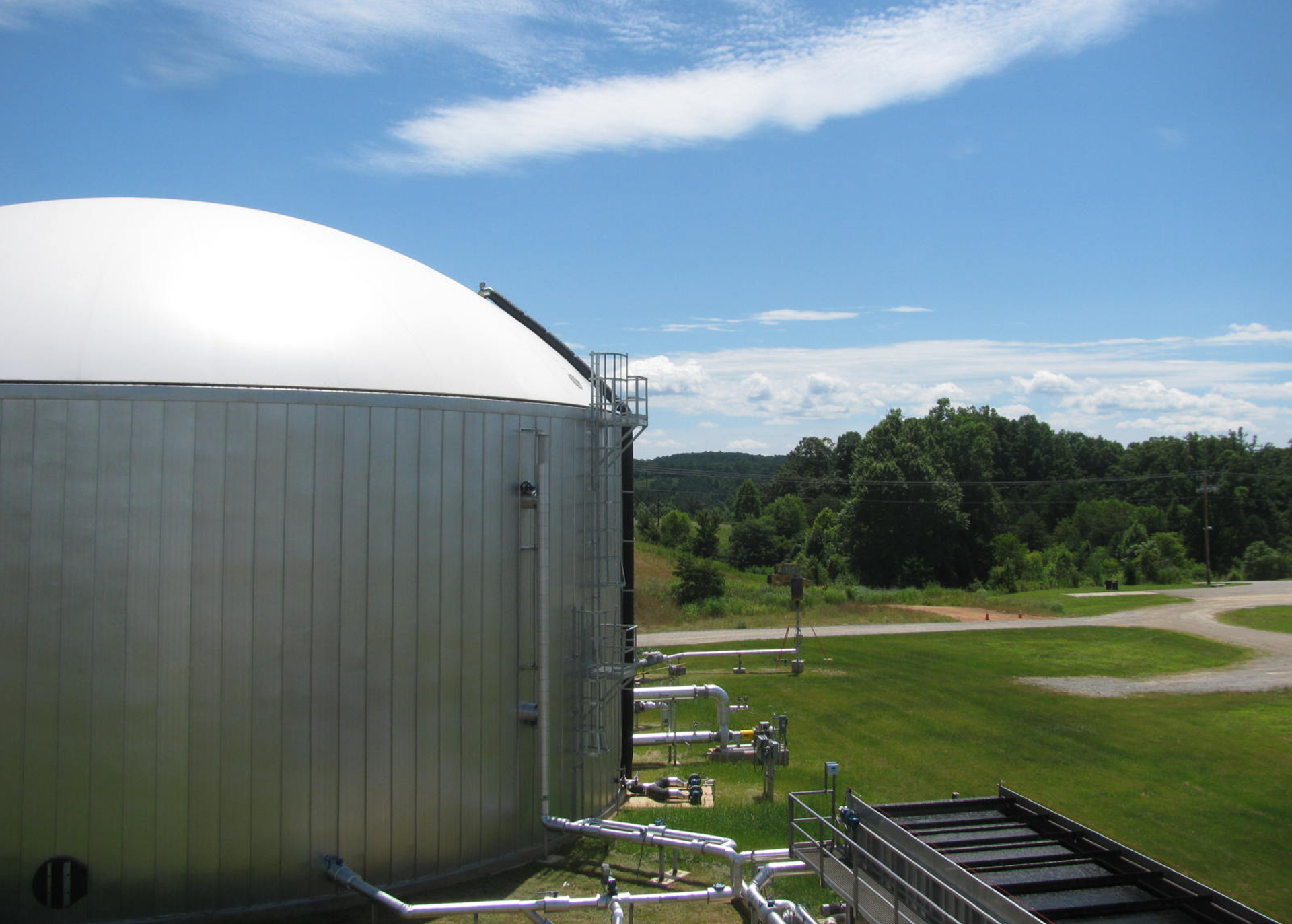

The facility includes a new 1.5 million gallon mixed anaerobic digester with a flexible dome cover to biologically degrade waste loads, converting to biogas. The digester was followed by a dissolved air flotation unit (DAF) that separates and returns the anaerobic biomass to the digester, while liquids pass through for subsequent treatment. A 100,000 gallon aerobic moving bed biofilm reactor (MBBR) further treats the liquid steam; bringing the plant effluent within discharge limits. A second DAF separates solids, with those returning to the digester while discharge liquid is pumped to the receiving sewer. A 50,000 gallon tank to store excess solids from the digester DAF. These are hauled off by truck and land applied as soil amendment.

The energy recovery system consists of a 400 kW packaged engine-generator that utilizes the biogas produced by anaerobic treatment to generate electricity and heat for use within the Monogram facilities. A containerized 1.5 MBTU/hr natural gas boiler was also provided as a backup for digester heating.

Improvements to an existing wastewater equalization tank to accommodate the new process was also performed. The tank was covered with a fixed fiberglass roof and the existing aeration equipment in that tank was replaced with pump mixing. Tankage and equipment allows Monogram to feed waste solid food and captured grease into the treatment system. By running them through the digester, Monogram was able to significantly reduce the waste solids weight and volume, and the digestion of these waste streams resulted in additional biogas production and hence additional electrical and heat generation.